C.S. SIMMONS ENGINEERING LTD

Mill Road Trading Estate

Radstock, Bath BA3 5TX

Mill Road Trading Estate

Radstock, Bath BA3 5TX

Tel: +44 (0)1761 433944

Fax: +44 (0)1761 437901

Email: mail@cssimmons.co.uk

Fax: +44 (0)1761 437901

Email: mail@cssimmons.co.uk

NIMONIC 80A CNC MACHINED COMPONENT

C276 NICKEL ALLOY HASTALLOY CNC MACHINED SHAFTS

INCONEL 625 CNC TURNED COMPONENT

UNS S32760 SUPER DUPLEX MACHINED COMPONENT

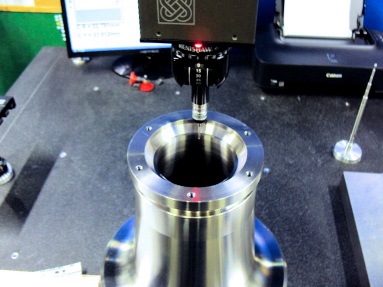

SUPER DUPLEX COMPONENT BEING MEASURED

HASTELLOY C276 CNC MACHINED COMPONENT

* All trademarks, logos and serviced marks mentioned on this website are the trademarks or service marks of their respective owners. In particular, Monel and Inconel are

* registered trademarks of Inco Alloys/Special Metals, Hastelloy is a registered trademark name of Haynes International, Inc., 17-4 PH is a registered trademark of AK Steel

* Corporation, Zeron is a registered trademark of Weir Materials & Foundries and Waspalloy is a registered trademark of United Technologies.

* registered trademarks of Inco Alloys/Special Metals, Hastelloy is a registered trademark name of Haynes International, Inc., 17-4 PH is a registered trademark of AK Steel

* Corporation, Zeron is a registered trademark of Weir Materials & Foundries and Waspalloy is a registered trademark of United Technologies.

CNC Machining of Specialist Steels

C.S. Simmons Engineering prides itself on its ability to machine the more exotic materials such as Inconel, Hastelloy, Monel, 17-4 PH, S316 Super Duplex, Zeron 100 and Waspalloy.*

In our factory all of these materials have been successfully machined, as well as many other specialist alloys, for oil, defence and many other industry applications.

List of Common Super Alloys Names

Hastelloy - Also known as: ASTM B574 Din 17752, Hastelloy C276 / C22 and UNS N010276

Inconel 718 – Also known as: AMS 5596, AMS 5662, ASTM B637 and UNS N07718 - A Very Versatile High Temperature and Corrosion Resistant Alloy.

Inconel 625 - Also known as: Inconel Alloy 625, Chronin 625, Altemp 625, Haynes 625, Nickelvac 625 and Nicrofer 6020.

Monel K500 - Also known as: ASTM B865 N05500, BS 3076:1989 NA18, DIN 2.4375, AMS 4676 and QQ-N-286.

Monel K400 – Also known as: Alloy 400, UNS N04400, BS 3076 NA13 and ASTM B164 (VO2.04).

Ni Hard – White cast irons, alloyed with Nickel and Chromium, Ni Hard 1, Ni Hard 2, Ni Hard 4 and Ni Hard 5.

Nimonic 80A - Also known as: Nickel 80A, Nimonic 80A and UNS N07080 - An alloy very resistant to chemicals, physical damage, oxidation and exhibits high tensile strength and creep rupture properties.

Super Duplex – Available in the following grades: UNS S32760, Zeron 100, FG and FLT fastener grades.

Titanium – Grades 2, 5 and BETA-C AMS6921A (Grade 19).

In our factory all of these materials have been successfully machined, as well as many other specialist alloys, for oil, defence and many other industry applications.

List of Common Super Alloys Names

Hastelloy - Also known as: ASTM B574 Din 17752, Hastelloy C276 / C22 and UNS N010276

Inconel 718 – Also known as: AMS 5596, AMS 5662, ASTM B637 and UNS N07718 - A Very Versatile High Temperature and Corrosion Resistant Alloy.

Inconel 625 - Also known as: Inconel Alloy 625, Chronin 625, Altemp 625, Haynes 625, Nickelvac 625 and Nicrofer 6020.

Monel K500 - Also known as: ASTM B865 N05500, BS 3076:1989 NA18, DIN 2.4375, AMS 4676 and QQ-N-286.

Monel K400 – Also known as: Alloy 400, UNS N04400, BS 3076 NA13 and ASTM B164 (VO2.04).

Ni Hard – White cast irons, alloyed with Nickel and Chromium, Ni Hard 1, Ni Hard 2, Ni Hard 4 and Ni Hard 5.

Nimonic 80A - Also known as: Nickel 80A, Nimonic 80A and UNS N07080 - An alloy very resistant to chemicals, physical damage, oxidation and exhibits high tensile strength and creep rupture properties.

Super Duplex – Available in the following grades: UNS S32760, Zeron 100, FG and FLT fastener grades.

Titanium – Grades 2, 5 and BETA-C AMS6921A (Grade 19).

Certificate

No. 9835

No. 9835

C. S. SIMMONS ENGINEERING LTD

CNC PRECISION MACHINING OF HIGH-PERFORMANCE AND SUPER ALLOYS TO 2.5M LENGTH, 0.8M DIAMETER AND 1.2M CUBED

REGISTERED OFFICE: MILL ROAD INDUSTRIAL TRADING ESTATE, FROME HILL, RADSTOCK, BATH, SOMERSET, ENGLAND BA3 5TX | COMPANY NO. 01253963

TEL: +44 (0)1761 433944 | FAX: +44 (0)1761 437901 | CONTACT US | EMAIL: SALES@CSSSIMMONS.CO.UK | WEB: WWW.CSSIMMONS.CO.UK

TOP OF PAGE | HOME | ABOUT US | MARKETS | BROCHURE | FIND US | CONTACT US | SITE MAP | MANUFACTURING SERVICES | SPECIALIST MATERIALS | 2.5M LENGTHS

LARGE COMPONENT MACHINING | 1.2 METRE CUBED MACHINING CAPACITY | COMPLEX COMPONENT MACHINING | PROTOTYPE CNC MACHINING | CNC MACHINED CASTINGS

REVERSE ENGINEERING | WELDING | PRODUCTION CONTROL | QUALITY | OUR FACTORY | CAPACITY LIST | DOWNLOADS | VACANCIES | LINKS | LEGAL | COOKIE POLICY

Website by www.practicalservices.co.uk | © Copyright 2008-2021 C.S. Simmons Engineering Ltd

CNC PRECISION MACHINING OF HIGH-PERFORMANCE AND SUPER ALLOYS TO 2.5M LENGTH, 0.8M DIAMETER AND 1.2M CUBED

REGISTERED OFFICE: MILL ROAD INDUSTRIAL TRADING ESTATE, FROME HILL, RADSTOCK, BATH, SOMERSET, ENGLAND BA3 5TX | COMPANY NO. 01253963

TEL: +44 (0)1761 433944 | FAX: +44 (0)1761 437901 | CONTACT US | EMAIL: SALES@CSSSIMMONS.CO.UK | WEB: WWW.CSSIMMONS.CO.UK

TOP OF PAGE | HOME | ABOUT US | MARKETS | BROCHURE | FIND US | CONTACT US | SITE MAP | MANUFACTURING SERVICES | SPECIALIST MATERIALS | 2.5M LENGTHS

LARGE COMPONENT MACHINING | 1.2 METRE CUBED MACHINING CAPACITY | COMPLEX COMPONENT MACHINING | PROTOTYPE CNC MACHINING | CNC MACHINED CASTINGS

REVERSE ENGINEERING | WELDING | PRODUCTION CONTROL | QUALITY | OUR FACTORY | CAPACITY LIST | DOWNLOADS | VACANCIES | LINKS | LEGAL | COOKIE POLICY

Website by www.practicalservices.co.uk | © Copyright 2008-2021 C.S. Simmons Engineering Ltd

1 off to 100 off batches

Lean manufacturing

methods employed

Quality certifications

& approvals (Please ask)

ASTM compliant

welding services

Extensive capacity

Quick turnaround

(Try us, we like a challenge)

Same day competitive

quotations

Job processing software

for traceability before,

during & after machining

Peace of mind for you

Lean manufacturing

methods employed

Quality certifications

& approvals (Please ask)

ASTM compliant

welding services

Extensive capacity

Quick turnaround

(Try us, we like a challenge)

Same day competitive

quotations

Job processing software

for traceability before,

during & after machining

Peace of mind for you