C.S. SIMMONS ENGINEERING LTD

Mill Road Trading Estate

Radstock, Bath BA3 5TX

Mill Road Trading Estate

Radstock, Bath BA3 5TX

Tel: +44 (0)1761 433944

Fax: +44 (0)1761 437901

Email: mail@cssimmons.co.uk

Fax: +44 (0)1761 437901

Email: mail@cssimmons.co.uk

Certificate

No. 9835

No. 9835

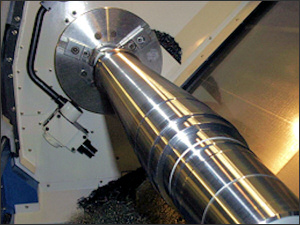

At just over 2 metres long this valve shaft was machined from UNS S32760 Super Duplex, for machinery used in the oil industry.

The shaft was turned on our Daewoo Puma 400 Turning Centre. All drilling and keyway operations were carried out on our Vertical and Horizontal Machining Centres.

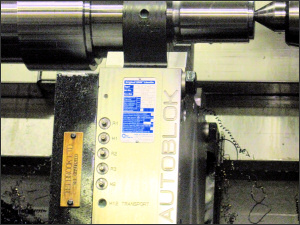

Daewoo Puma 400LA CNC Turning Centre

Equipped with Fanuc 18i control system. Fully programmable tailstock. Fully retrofitted SMV Autoblock steady (Workpeice: 230mm max. dia. – 30mm min. dia.)

Maximum Turning Diameter — 580mm

Length Z-axis 2200mm (MAX Workpiece length, ideal for machining long shafts accurately)

Chuck Dia(IN) — 18"

Max swing over bed — 800mm

The shaft was turned on our Daewoo Puma 400 Turning Centre. All drilling and keyway operations were carried out on our Vertical and Horizontal Machining Centres.

Daewoo Puma 400LA CNC Turning Centre

Equipped with Fanuc 18i control system. Fully programmable tailstock. Fully retrofitted SMV Autoblock steady (Workpeice: 230mm max. dia. – 30mm min. dia.)

Maximum Turning Diameter — 580mm

Length Z-axis 2200mm (MAX Workpiece length, ideal for machining long shafts accurately)

Chuck Dia(IN) — 18"

Max swing over bed — 800mm

CNC Machining to 2.5m Length

NEW FOR 2019 - HYUNDAI-WIA L500LMA AND STEADY REST TYPE RX-5-Z 75-430

Hyundai-Wia L500LMA CNC Turning Centre

Equipped with Fanuc 18i Control System and

Steady Rest Type RX-5-Z 75-430 (Workpiece: 430mm max. dia. – 30mm min. dia.)

Maximum Turning Diameter — 690mm

Live Tools ER40 (03-025mm Tool Fitting / 140 N Maximum Torque)

Length Z-axis 2500mm (maximum workpiece length, ideal for machining long shafts accurately)

Chuck diameter — 24"

Maximum swing over bed — 1030mm

C. S. SIMMONS ENGINEERING LTD

CNC PRECISION MACHINING OF HIGH-PERFORMANCE AND SUPER ALLOYS TO 2.5M LENGTH, 0.8M DIAMETER AND 1.2M CUBED

REGISTERED OFFICE: MILL ROAD INDUSTRIAL TRADING ESTATE, FROME HILL, RADSTOCK, BATH, SOMERSET, ENGLAND BA3 5TX | COMPANY NO. 01253963

TEL: +44 (0)1761 433944 | FAX: +44 (0)1761 437901 | CONTACT US | EMAIL: SALES@CSSSIMMONS.CO.UK | WEB: WWW.CSSIMMONS.CO.UK

TOP OF PAGE | HOME | ABOUT US | MARKETS | BROCHURE | FIND US | CONTACT US | SITE MAP | MANUFACTURING SERVICES | SPECIALIST MATERIALS | 2.5M LENGTHS

LARGE COMPONENT MACHINING | 1.2 METRE CUBED MACHINING CAPACITY | COMPLEX COMPONENT MACHINING | PROTOTYPE CNC MACHINING | CNC MACHINED CASTINGS

REVERSE ENGINEERING | WELDING | PRODUCTION CONTROL | QUALITY | OUR FACTORY | CAPACITY LIST | DOWNLOADS | VACANCIES | LINKS | LEGAL | COOKIE POLICY

Website by www.practicalservices.co.uk | © Copyright 2008-2021 C.S. Simmons Engineering Ltd

CNC PRECISION MACHINING OF HIGH-PERFORMANCE AND SUPER ALLOYS TO 2.5M LENGTH, 0.8M DIAMETER AND 1.2M CUBED

REGISTERED OFFICE: MILL ROAD INDUSTRIAL TRADING ESTATE, FROME HILL, RADSTOCK, BATH, SOMERSET, ENGLAND BA3 5TX | COMPANY NO. 01253963

TEL: +44 (0)1761 433944 | FAX: +44 (0)1761 437901 | CONTACT US | EMAIL: SALES@CSSSIMMONS.CO.UK | WEB: WWW.CSSIMMONS.CO.UK

TOP OF PAGE | HOME | ABOUT US | MARKETS | BROCHURE | FIND US | CONTACT US | SITE MAP | MANUFACTURING SERVICES | SPECIALIST MATERIALS | 2.5M LENGTHS

LARGE COMPONENT MACHINING | 1.2 METRE CUBED MACHINING CAPACITY | COMPLEX COMPONENT MACHINING | PROTOTYPE CNC MACHINING | CNC MACHINED CASTINGS

REVERSE ENGINEERING | WELDING | PRODUCTION CONTROL | QUALITY | OUR FACTORY | CAPACITY LIST | DOWNLOADS | VACANCIES | LINKS | LEGAL | COOKIE POLICY

Website by www.practicalservices.co.uk | © Copyright 2008-2021 C.S. Simmons Engineering Ltd

1 off to 100 off batches

Lean manufacturing

methods employed

Quality certifications

& approvals (Please ask)

ASTM compliant

welding services

Extensive capacity

Quick turnaround

(Try us, we like a challenge)

Same day competitive

quotations

Job processing software

for traceability before,

during & after machining

Peace of mind for you

Lean manufacturing

methods employed

Quality certifications

& approvals (Please ask)

ASTM compliant

welding services

Extensive capacity

Quick turnaround

(Try us, we like a challenge)

Same day competitive

quotations

Job processing software

for traceability before,

during & after machining

Peace of mind for you